A local Seattle small business recently came to us with an interesting print project.

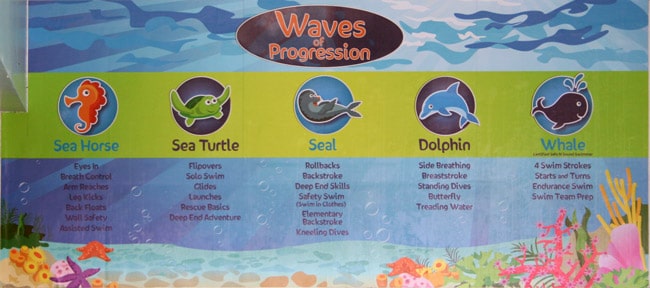

Safe N Sound Swimming is Seattle’s premier, family owned and operated, swimming lessons provider. For the past 27 years they have been teaching kids how to swim and be safe in the water. They designed a large graphic wall piece to visually communicate swimming proficiency levels among their students. The final size was 144.5” x 65.5”. It was to be displayed on a wall of their indoor swimming pool facility.

They needed a cost-effective and flexible print solution. We had just the thing for them — visual magnetics.

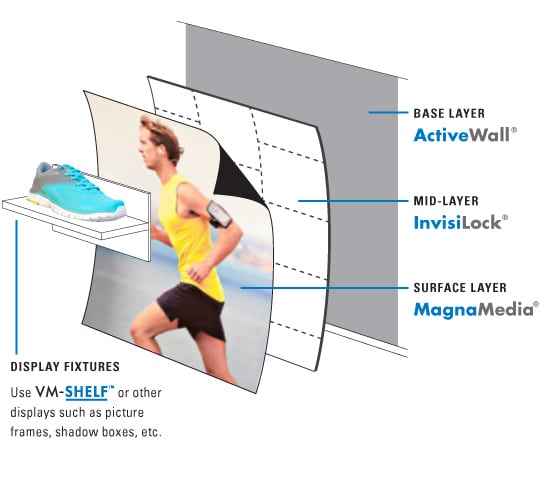

The Benefits of the Visual Magnetics System

Our high-performance visual magnetic-receptive technologies have three main benefits.

1. Easy Installation

Can be installed by company employees without the need for outside vendor assistance

2. Stability

Custom engineered for strength, ensuring that your printed media stays in place

3. Flexibility

Can be applied to almost any surface, and the printed graphic panels can easily be removed, replaced or updated

This short video demonstrates how the system works and just how flexible it can be.

Installation

There was some concern that the magnetic system could not withstand the conditions of the indoor pool facility. Temperatures regularly reach above 90 degrees, and the pool water has a habit of getting everywhere (including on walls). We installed some test magnets, left them up for a couple of weeks to see how they would respond. As expected, the magnets performed up to code. The temperature and water had no adverse effects on the strength of the system.

The visual magnetics system is easy enough to install on your own, however, Safe N Sound preferred that we handle the install. It was not a problem. This is how it works:

Step 1: Cover the desired wall area with a special latex primer

The primer is not magnetic itself, rather, it is high in iron content. It acts as a magnetic receptive for the magnets to attract to the painted wall surface.

Step 2: Apply the InvisiLok magnet to the painted wall surface

This flexible magnet backer magnetically locks into place over the primer painted area. Due to the overall size of the wall display, the 30 mil high-energy magnet was required.

Step 3: Apply the printed media graphic panels

The graphic panels are printed on a VM-Poly 8 mil satin substrate. The material has a magnetic receptive coating on the reverse side, specially designed to attract to the magnets. For installation, the panels were simply unrolled, smoothed out and magnetically attached to wall.

The panels were printed on our HP Scitex FB 700 UV Inkjet grand format digital press. On the wall, it appears as one seamless piece of printed media. It is actually three separate pieces. Smaller sized panels are easier to handle and install.

Additionally, the panels were coated with an anti-graffiti laminate for protection against unwanted scuffs.

One of the great things about the visual magnetics system is the ability to add multiple layers of magnets. The “Waves of Progression” is actually a separate printed element, and so are the cute animals. These 3D images are layered over the top of the backing panel. They were printed on canvas finished ¼’ foamcore (also on the Scitex press). Self-adhesive magnets were applied to the back of each piece, enabling them to be magnetically secured to the wall.

Moving Forward

We installed this large wall display last summer and it is still in great shape. When the time comes for them to swap out the design with something new, we will be more than ready to print it up.

For more information about our visual magnetic system and what it can do for your business, please drop us a line. We would love to hear from you!

Email: contact@alphagraphicsseattle.com

phone: 206-448-9100